Highly dynamic linear guides

In the industrial sector, saving energy and increasing efficiency are decisive factors for success. Highly dynamic linear guides play a central role in this. The ability to reduce cycle times and therefore manufacturing times leads directly to increased efficiency and enables companies to achieve more output while simultaneously reducing manufacturing costs. But which possibilities are there to achieve even more dynamics in your production processes?

Dynamics through lightweight construction: maximising efficiency and acceleration

A key aspect of highly dynamic movements is low weight. Lightweight components facilitate the acceleration of linear guides and allow the use of smaller, energy-saving drives. This not only reduces costs, but also increases the overall performance of the machines and systems.

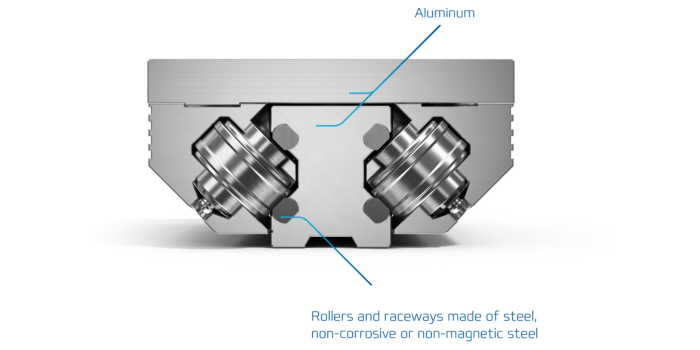

By using lightweight materials such as aluminium or plastic and state-of-the-art manufacturing techniques, Franke linear systems enable substantial weight, energy and space savings. They guarantee maximum precision over the entire service life. Base bodies made of aluminium halve the weight of the linear guides compared to conventional steel guides and require only a fraction of the drive energy for acceleration and movement.

Read more here.

Industry best practice: Linear systems in the packaging industry

In the packaging industry, high dynamics are crucial in order to meet the increasing demands for speed and precision. Packaging machines must move machine units quickly and safely using linear guides in order to achieve high cycle rates. These dynamic movement patterns are essential in order not to interrupt the production flow and to ensure efficient packaging.

It becomes particularly challenging when two units need to be moved on one axis, as this requires precise coordination and fast acceleration. Highly dynamic linear guides make it possible to fulfil these complex requirements and thus make a significant contribution to the performance and efficiency of packaging machines.

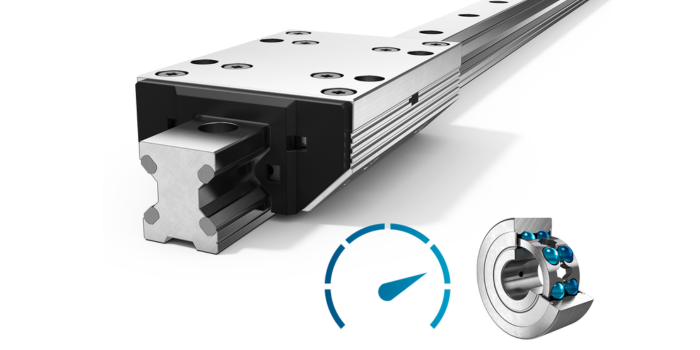

The highly dynamic linear guide FDH is ideal for this application: the double-row angular contact ball bearing as a track roller enables accelerations of up to 100 m/s².

In addition, the linear guide is double-sealed, which prevents lubricant from leaking and keeps the packaging clean and protected. The closed rollers also offer improved protection against contamination, which increases their longevity even under dynamic environmental conditions.

Franke linear guides can be ordered quickly and easily via the MeinFranke online shop. The delivery time is two weeks (even for customised lengths)*

If you want to optimise your production processes and increase your competitiveness, the use of highly dynamic linear guidance systems is the key to success!

We are happy to advise you! Send a direct message to our customer advisors here.

*May differ slightly for customised products.