Weight optimisation for rolling bearings

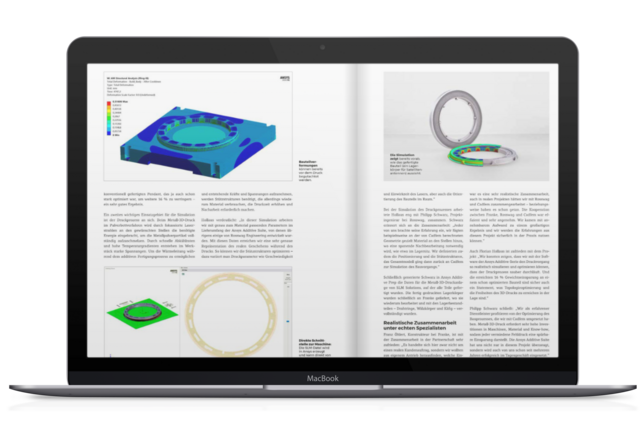

Find out how topology optimisation makes it possible to reduce the weight of a 3D-printed bearing body. Compared to an already highly optimised, conventionally manufactured counterpart, a further 16 percent saving is possible!

In collaboration with simulation experts and solution providers for 3D printing in metal, we have succeeded in pushing lightweight construction technology to its limits.

Read more in our free case study!